The zinc layer thickness standard for hot dip galvanized steel coils is a technical specification determined based on specific application scenarios and anti-corrosion requirements. The following is a detailed analysis of the zinc layer thickness standard for hot dip galvanized steel coils:

1. Standard Overview

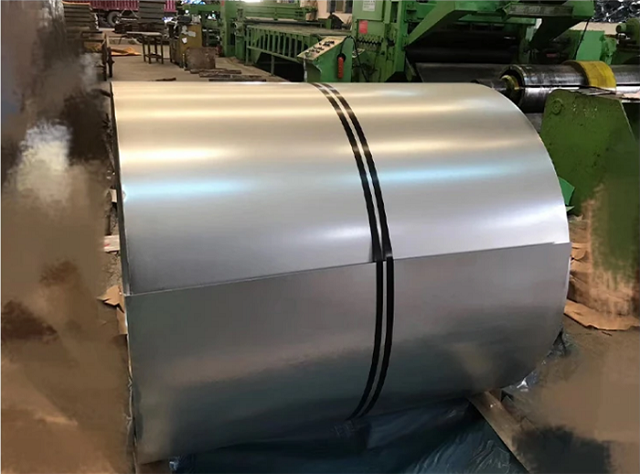

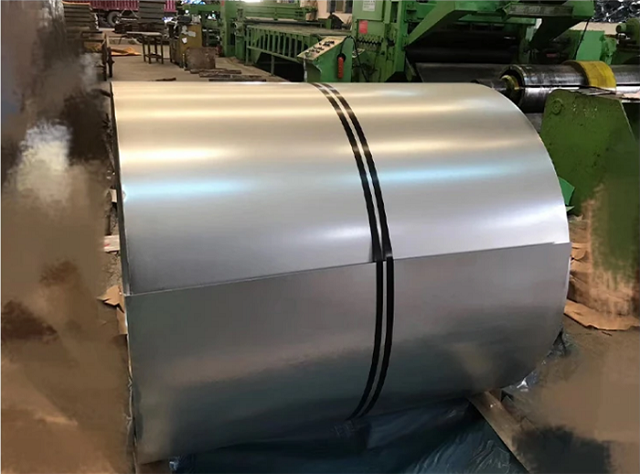

Hot dip galvanizing is a process of immersing steel components in molten zinc solution and generating a layer of zinc iron alloy and pure zinc on the surface of the steel through physical and chemical reactions. This zinc layer can effectively isolate steel from corrosive factors in the external environment, thereby significantly improving the corrosion resistance of steel. The thickness of the zinc layer on hot dip galvanized steel coils is one of the important indicators for evaluating their anti-corrosion performance.

2. Zinc layer thickness standard

The zinc layer thickness standard for hot dip galvanized steel coils is usually formulated based on relevant national or industry standards. Here are some common zinc layer thickness standards:

1. According to the thickness of the workpiece:

When the thickness of the workpiece is greater than or equal to 6 millimeters, the average thickness of the hot-dip galvanized layer should be greater than 85 microns. The local thickness may vary, but there are generally certain requirements, such as greater than 70 microns.

When the thickness of the workpiece is less than 6 millimeters but greater than 3 millimeters, the average thickness of the hot-dip galvanized layer should be greater than 75 microns, with similar requirements for local thickness.

When the thickness of the workpiece is less than 3 millimeters but greater than 1.5 millimeters, the average thickness of the hot-dip galvanized layer should be greater than 55 microns, and local thickness may require greater than 45 microns.

2. Standards for specific products:

For certain specific products, such as hot-dip galvanized cable trays, the standard for the thickness of the galvanized layer may be more specific.

3. Industry or enterprise standards:

In addition to national and industry standards, some companies may also develop stricter zinc layer thickness standards based on their own production processes and product requirements.

3. Influencing factors

The thickness of the zinc layer on hot dip galvanized steel coils is influenced by various factors, including galvanizing process parameters, steel material, pre plating treatment, and post plating treatment. Therefore, it is necessary to strictly control these parameters during the production process to ensure the uniformity and consistency of the zinc layer thickness.

4. Testing and Verification

In order to ensure that the zinc layer thickness of hot dip galvanized steel coils meets the standard requirements, strict testing and verification are usually required. This includes using professional coating thickness gauges to measure the thickness of the zinc layer, as well as verifying the corrosion resistance of the zinc layer through methods such as salt spray testing and copper sulfate corrosion testing.

In summary, the zinc layer thickness standard for hot dip galvanized steel coils is a technical specification determined based on specific application scenarios and anti-corrosion requirements. In practical applications, it is necessary to strictly control the thickness of the zinc layer according to relevant standards or requirements to ensure the anti-corrosion performance and service life of the product.

Language

▼

Language

▼