Prepainted galvanized steel coil is a metal coil that combines galvanizing and color coating processes. It combines the corrosion resistance of galvanized steel plates with the aesthetic decoration of color coated plates. The production process of prepainted galvanized steel coils mainly includes the following key steps:

1、 Galvanized treatment

1. Zinc dipping: Dip the steel plate into a molten zinc bath to adhere a layer of zinc on its surface, forming a dense galvanized layer. This step is the foundation for enhancing the corrosion resistance of steel plates.

2. Annealing treatment: The galvanized steel plate is annealed to improve the adhesion and uniformity of the coating. Annealing treatment can also eliminate internal stress in steel plates and improve their processing performance.

3. Other treatments: In some cases, the steel plate may also undergo alloying treatment, which involves heating the steel plate to a certain temperature (such as around 500 ℃) to form an alloy film of zinc and iron, further enhancing the adhesion and weldability of the coating.

2、 Color coating treatment

1. Pre treatment: Before color coating, it is necessary to pre treat the prepainted galvanized steel coil, including steps such as cleaning, degreasing, and rust removal, to ensure good bonding between the color coating and the steel plate substrate.

2. Painting: Roll coating or other painting methods are used to evenly apply colored coatings on the surface of galvanized steel plates. The selection of coatings should be determined based on the product's usage environment and performance requirements.

3. Curing: The coated steel plate is sent to a curing furnace for heating treatment, causing the coating to undergo chemical reactions at high temperatures, forming a hard and durable colored coating. The curing temperature and time need to be precisely controlled according to the type and requirements of the coating.

3、 Post processing and inspection

1. Cooling: The cured steel plate needs to be cooled to stabilize the coating performance.

2. Quality inspection: Inspect the appearance quality, coating thickness, adhesion and other items of prepainted galvanized steel coils to ensure that the products meet relevant standards and customer requirements.

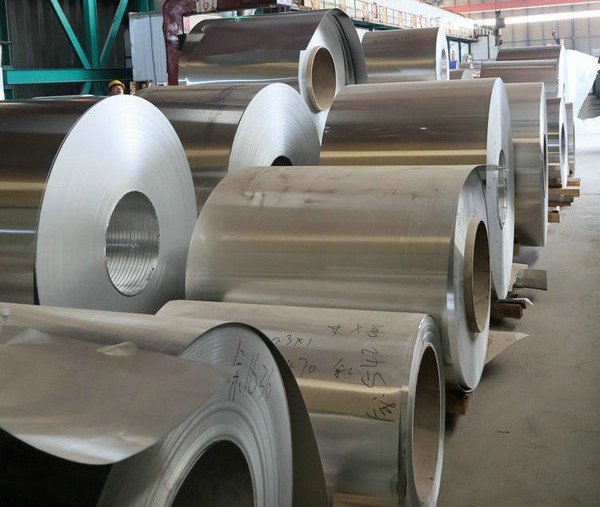

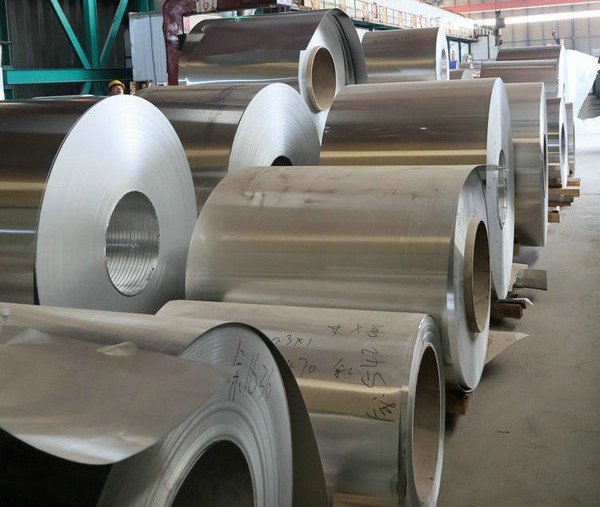

3. Rolling and packaging: According to customer needs and transportation requirements, the prepainted galvanized steel coils are rolled and packaged for easy transportation and storage.

In summary, the production process of prepainted galvanized steel coils is a complex and delicate process, involving multiple links and parameter control. Through strict process control and quality inspection, the quality and performance of prepainted galvanized steel coils can be ensured to meet relevant standards and customer requirements.

Language

▼

Language

▼