Language

▼

Language

▼

More Language

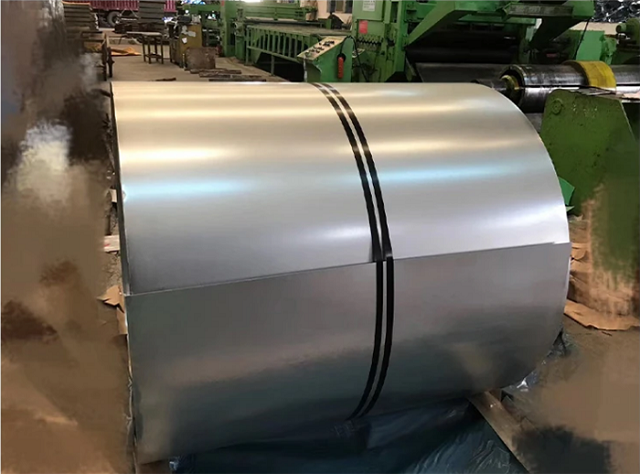

In the field of metal processing and storage, galvanized steel sheet, as an important anti-corrosion material, is widely used in multiple industries such as construction, automobiles, and home appliances. However, during storage, especially in humid environments, its performance and quality may be significantly affected. This is undoubtedly a highly concerning issue for galvanized steel sheet factory,manufacturers. The specific impact of storing in a humid environment on galvanized steel sheets is mainly reflected in the following aspects:

A humid environment can promote the formation of electrolyte solution on the surface of galvanized steel sheets, thereby accelerating the electrochemical corrosion process. The galvanized layer is prone to react with oxygen, water vapor, and other corrosive substances in humid environments, causing the galvanized layer to gradually oxidize and peel off, exposing the steel substrate and making it more susceptible to corrosion.

A humid environment may also cause corrosion phenomena such as white rust and black spots on the galvanized layer. These corrosion products not only affect the aesthetics of galvanized steel sheets, but also damage the integrity of the galvanized layer and reduce its protective ability. Galvanized steel plates stored in humid environments for a long time may gradually thin out their galvanized layer, and even have local perforations, resulting in direct exposure of the steel substrate to corrosive environments.

As corrosion intensifies, the mechanical properties of galvanized steel sheets will gradually decrease. For example, its mechanical properties such as tensile strength and yield strength may decrease, making it more prone to deformation, fracture, and other failures during use. In addition, the weather resistance and wear resistance of galvanized steel sheets will also decrease due to long-term exposure to humid environments.

The corrosive effect of humid environment on galvanized steel sheet will significantly shorten its service life. Galvanized steel plates that could have been used for many years in normal environments may only be used for a few years or even shorter in humid environments. This not only increases maintenance costs, but may also pose safety hazards to equipment or structures using galvanized steel sheets.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust