Language

▼

Language

▼

More Language

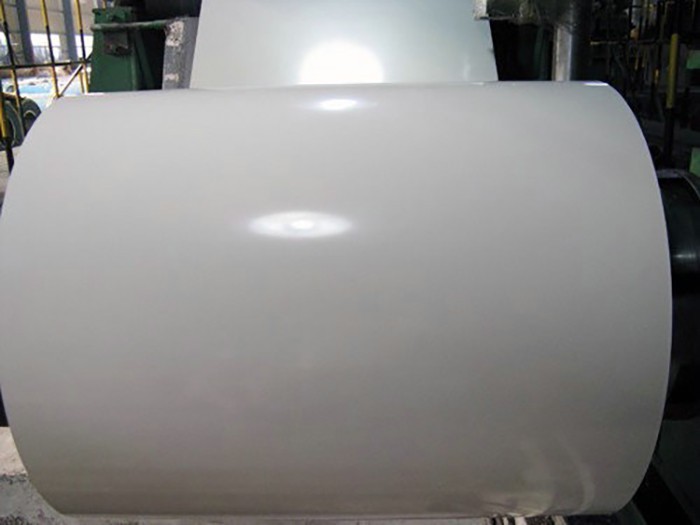

Color coated sheet is a composite material made by applying organic coating on the surface of metal sheet and curing it through baking. It combines the high strength of metal sheets with the excellent decorative and corrosion resistance of organic coatings, and is therefore widely used in various fields such as construction, home appliances, automobiles, furniture, etc. The color coated sheet manufacturer has organized the following aspects:

Regular cleaning of the surface of the color coated sheet is a fundamental step in maintaining its appearance and quality. You can use a soft cloth and appropriate cleaning agent to gently wipe the surface to remove dust and dirt. When cleaning, avoid using cleaning agents containing abrasives or highly corrosive chemicals to prevent damage to the coating of the color coated plate.

Although surface coatings have a certain degree of corrosion resistance, prolonged exposure to chemical substances such as acids, alkalis, etc. may still cause damage to the coating. Therefore, when using color coated sheets, direct contact with these chemicals should be avoided. If accidentally touched, rinse immediately with plenty of water and consult a professional for treatment as soon as possible.

The outer coating of color coated plates generally has good waterproof performance, but if they are exposed to moisture or water for a long time, it may still cause damage to the coating and rusting of the steel plate. Therefore, during installation, a good drainage system should be ensured to avoid water accumulation, especially at the joints of the color coated sheet. Meanwhile, when storing color coated sheets, they should also be avoided from being placed in damp environments.

Regular inspection of the coating condition on the surface of the color coated sheet is an important means of maintaining its quality and performance. The coating should be checked for detachment, scratches, or damage. Once a problem is found, it should be repaired promptly to prevent further damage to the coating. When repairing, a coating that matches the original coating should be used and applied according to the manufacturer's recommendations.

Although the coating has a certain degree of hardness, it is still easily scratched by sharp objects. Therefore, when using or storing color coated sheets, contact with sharp objects or tools should be avoided to avoid scratching the surface. At the same time, appropriate tools and methods should be used when handling and installing color coated panels to avoid damage to the coating.

Performance and quality may be affected by environmental temperature. In high temperature environments, color coated plates may deform due to thermal expansion; In low-temperature environments, coatings may harden and become fragile. Therefore, when installing and using color coated plates, attention should be paid to changes in ambient temperature and corresponding measures should be taken to reduce their impact on the color coated plates. For example, in high-temperature environments, measures such as shading or ventilation can be taken to reduce temperature; In low-temperature environments, preheating treatment can be carried out indoors.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust