Language

▼

Language

▼

More Language

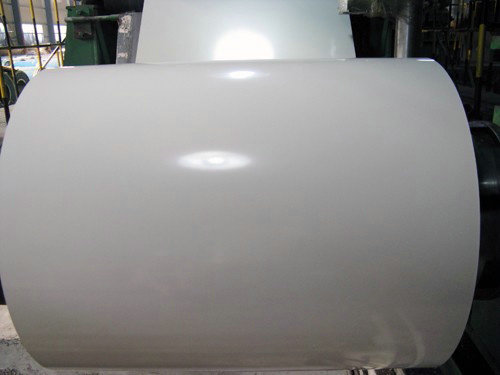

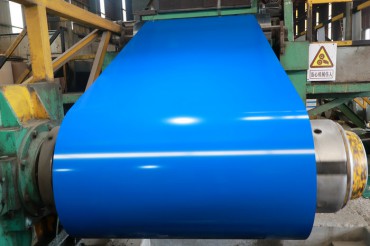

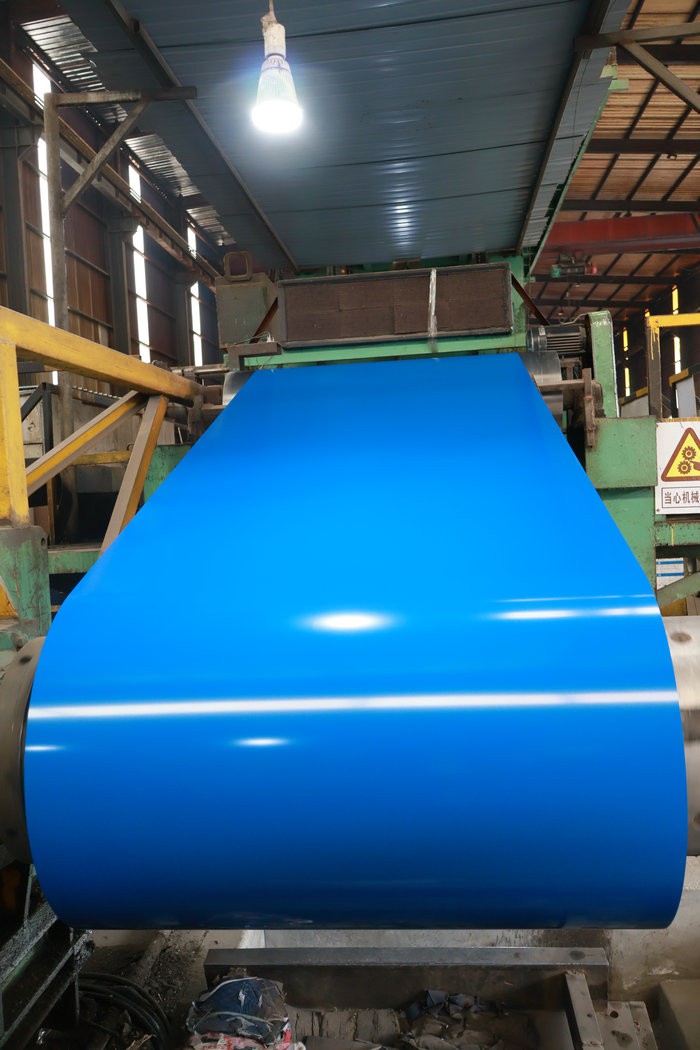

Color coated sheets (also known as pre-painted metal sheets) are materials made by applying multiple layers of organic coatings onto a metal substrate (such as galvanized steel or aluminum). They are widely used in construction, appliances, transportation, and other industries. Their key advantages include:

Rust Prevention: The base material (e.g., galvanized or galvalume steel) combined with chemical treatment (e.g., chromate passivation) provides strong anti-corrosion properties.

Coating Durability: Topcoats like polyester (PE), polyvinylidene fluoride (PVDF), and silicone-modified polyester (SMP) resist UV rays, acid rain, and salt spray, ensuring 10–20 years of outdoor service life.

Wide Selection: Available in various colors (RAL, Pantone) and finishes (glossy, matte, metallic, wood grain, stone effect, etc.) for customized designs.

Decorative Versatility: Ideal for architectural exteriors (e.g., roofing, cladding) and interior décor, enhancing visual appeal.

Low Weight: Lighter than traditional materials (e.g., concrete, stone), reducing structural load and installation costs.

Mechanical Strength: The metal substrate offers high tensile and bending strength, suitable for load-bearing structures and long-span constructions.

Formability: Can be easily cut, stamped, or bent for complex shapes (e.g., arched roofs, curved panels).

Quick Assembly: Installed via bolts, welding, or snap-on systems, enabling modular construction and reducing on-site labor.

Recyclable: Metal substrate is 100% recyclable, minimizing waste.

Energy-Saving: Reflective coatings (e.g., cool roofs) reduce heat absorption, lowering cooling costs.

Low Pollution: Advanced coatings (e.g., chromium-free treatments, water-based paints) reduce harmful emissions.

Special Coatings: Can be customized for additional properties:

Self-Cleaning: Photocatalytic coatings (e.g., TiO₂) break down dirt.

Antibacterial: Suitable for medical and food-processing environments.

Fire-Resistant: Flame-retardant coatings improve fire safety ratings.

Long Lifespan, Low Maintenance: No frequent repainting, reducing long-term upkeep costs.

Lower Lifecycle Cost: Though initial cost may be higher than plain steel, durability and efficiency make it more economical over time.

Construction: Factories, warehouses, stadiums, residential roofing/walls.

Appliances: Refrigerators, washing machine panels.

Transportation: Subway stations, tunnel linings.

Furniture: Office partitions, cabinet surfaces.

|

|

Color Coated Sheet |

Stainless Steel |

Painted Steel |

|

|

Corrosion Resistance |

★★★★☆ |

★★★★★ |

★★☆☆☆ |

|

|

Color Options |

★★★★★ |

★★☆☆☆ |

★★★☆☆ |

|

|

Cost |

★★★☆☆ |

★★★★★ |

★★☆☆☆ |

|

|

Workability |

★★★★★ |

★★★☆☆ |

★★★★☆ |

Color coated sheet offers a variety of color and texture options such as solid color and printing, and also provides customized services, whether it is simple style or personalized design, to meet customer needs.

Color coated sheet refers to a high-tech composite material obtained by applying organic coatings or films on the surface of thin steel plates, which combines the advantages of both organic polymers and steel plates. Color plates not only have good coloring, formability, and corrosion resistance of organic polymers, but also have the mechanical strength and easy processing properties of steel plates. They can be easily processed by punching, bending, deep drawing, riveting, welding, etc., and can be widely used in various industries.

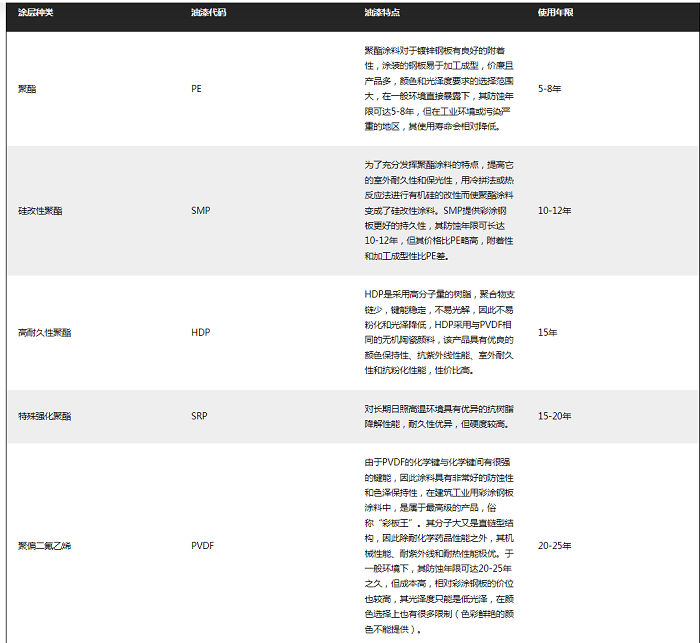

Color coated sheet is also called coated plate, color steel plate,color coated sheet, it is based on metal coil (cold rolled plate, hot galvanized plate, aluminum plate, high aluminum alloy plate, stainless steel plate, etc.) as the substrate, coated or laminated on the surface of various organic coatings or plastic films. Because it is a coil that completes the surface coating in a metallurgical plant, it can be directly processed into products by users, so it is also called pre-coated coil. Uses: industrial plant, gymnasium, airport/station, indoor partition, warehouse, elevator, metal curtain wall, etc Coating type:

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust