Language

▼

Language

▼

More Language

Nano-insulation anti-corrosion colored aluminum coil

Nano anticorrosive color aluminum coil provides a variety of colors and textures such as solid color, printing, etc., and can also provide customized services according to user's size needs.

The aluminum foil layer on the outer surface of the color steel plate can reflect sunlight and infrared heat energy off the surface of the metal plate. In the range of visible light wavelength 0.38-0.765m, the reflectance can reach 70%-80%, in the range of infrared light wavelength 0.76-505m, the reflectance can reach 75%-100%, and the heat insulation efficiency is high. Summer sunshine color steel surface is not hot. At the same time, the anti-aging adhesive firmly binds the surface nano anti-aging heat insulation film and the color steel plate together, effectively preventing corrosive gases in the air from entering the substrate, making the color steel plate not easy to rust. It is suitable for building roof and wall material of industrial plant, civil building, grain warehouse, steel structure plant. It is mainly used in large-scale hardware, chemical plants, ceramics factories, large-scale warehouses, wholesale markets, farmers' markets, animal husbandry, foundries, electroplating factories, chemical fertilizer plants, paper mills and other industrial plants.

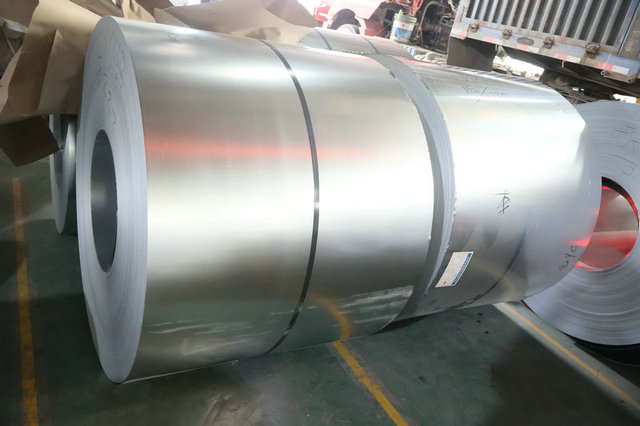

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust