Language

▼

Language

▼

More Language

The weight of color coated sheets mainly depends on factors such as substrate material, thickness, coating type, and coating weight. The following is a detailed analysis of the color coated sheet weight:

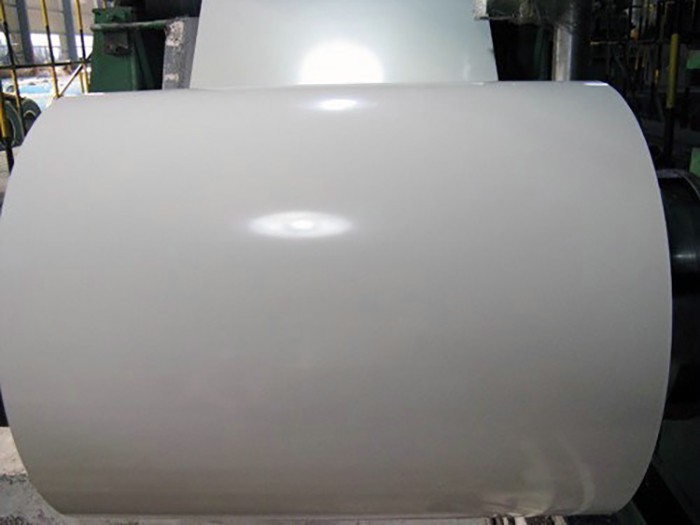

Color coated steel plates are usually made by surface coating or laminating various organic coatings or chemical coatings such as plastic films on substrates such as galvanized steel plates or aluminum zinc coated steel plates. The thickness of the substrate is one of the key factors affecting the weight of the color coated sheet. The common thickness range of color steel plates is from 0.3 millimeters to 1.2 millimeters, and the thicker the thickness, the heavier the weight per unit area. For example, a 0.3mm thick color steel plate weighs approximately 4 to 5 kilograms per square meter, while a 1.2mm thick color steel plate can weigh over 10 kilograms per square meter.

There are various types of coatings on color coated sheets, including polyester, fluorocarbon, etc. These coatings have a relatively small impact on the weight of the color coated sheet, but may also vary due to differences in coating thickness and density. In addition, the weight of the coating on the color coated sheet will also affect its total weight. The weight of the coating generally fluctuates within a certain range, and the specific value depends on the manufacturer's process standards and customer requirements. The coating weight range of new substrate materials such as high aluminum zinc aluminum magnesium substrates may also vary.

The color coated sheet weight can be calculated using the following formula: weight per meter=thickness x width x 7.85 (steel plate density, in g/cm ³, converted to kg/m ² needs to be multiplied by 1000 and then divided by 1000000, but in this formula, it is directly calculated as 7.85, and the result is still in kg, which is a similar calculation). However, this formula is only applicable for calculating the weight of uncoated pure steel plates. For color coated sheets, the actual weight may be slightly greater than this calculated value due to the presence of coatings and plating layers. Therefore, when calculating the weight of color coated sheets, it is usually necessary to refer to the specific parameters of the manufacturer or conduct actual weighing.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust