Language

▼

Language

▼

More Language

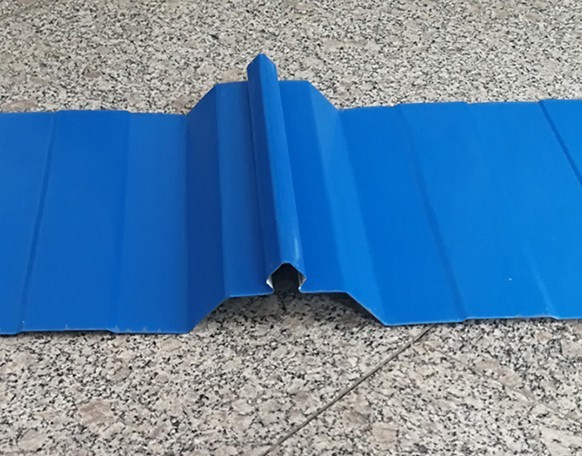

Color steel tile roof, as a widely used roofing material in industrial, commercial, and civil buildings, has significant performance advantages. The following is a detailed explanation of the performance advantages of color steel tile roof manufacturer:

The color steel tile roof is made of lightweight materials, but has high strength characteristics. This enables it to reduce the overall weight of the building while ensuring its safety, which is beneficial for the stability and energy efficiency of the building. The lightweight and high-strength characteristics also make the color steel tile roof perform well in withstanding wind and snow loads, which can resist the impact of harsh weather and ensure the durability of the building.

Featuring a variety of colors and patterns to meet the aesthetic needs of different customers. The bright colors and unique waveform design of the color steel tile roof make the building appearance more beautiful and elegant, enhancing the overall quality of the building. At the same time, it also has good reflective performance, which can reduce the radiation heat of the sun to a certain extent, lower indoor temperature, and improve the comfort of the building.

Installation and construction are relatively simple and fast. It adopts a dry construction method, which eliminates the need for wet work and greatly shortens the construction period. In addition, it is lightweight, easy to handle and install, reducing construction difficulty and cost. This gives color steel tile roofs significant advantages in construction projects with tight schedules or the need for rapid construction.

The color steel tile roof is closely connected to the building structure and has good seismic performance. During natural disasters such as earthquakes, it can effectively absorb and disperse seismic energy, reducing the degree of damage to building structures. This characteristic makes it widely applicable in earthquake prone areas.

Color steel tile roofing materials have excellent fire resistance. It is made of flame-retardant or non combustible materials, which can effectively prevent the spread of fire. In the event of a fire, maintaining the integrity of the structure provides valuable time for evacuation and rescue. This characteristic makes color steel tile roofs play an important role in buildings that require high fire resistance.

After special treatment, it has excellent corrosion resistance. It can resist the erosion of chemicals such as acid, alkali, salt, etc., extending its service life. This characteristic makes color steel tile roofs widely applicable in humid and highly corrosive environments.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust