Language

▼

Language

▼

More Language

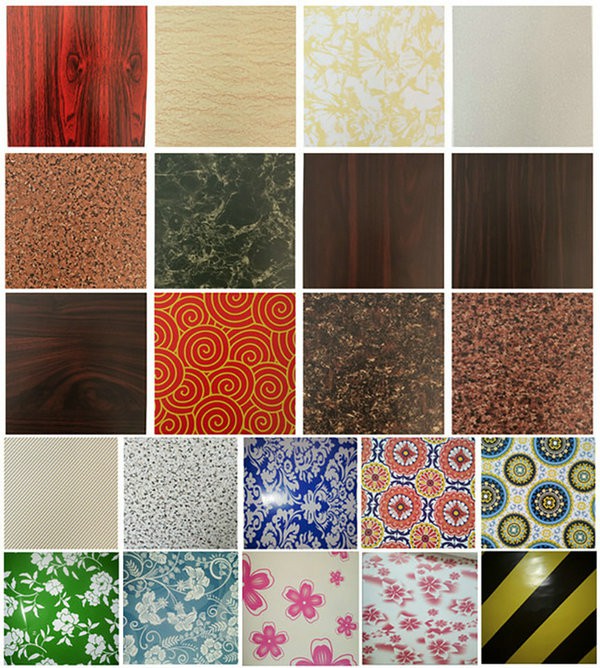

Color aluminum sheet is a new type of building materials, not only can greatly increase the stability of the house, but also allows us to add more color to the house.

Color aluminum sheet has a top coat, primer, back coating paint, back coating paint mainly plays a role in antioxidant, the specific coating process includes the following aspects, semi-finished products - on the machine - molding - under the pieces and inspection - packaging and warehousing, in the surface of the aluminum plate can be painted to make the color of the aluminum plate a longer service life.

Color aluminum sheet is through the necessary degreasing and chemical treatment of the surface of the aluminum plate, will be high-quality paint roll coating on the surface, the paint on the surface of the aluminum plate drying and curing and become. The flatness of the paint film on the surface of the roller coated panel is higher than that of the sprayed panel. The color is divided into pearlescent and matte, and the common ones on the market are mostly pearlescent. Its price is higher than spraying. The biggest feature of the roller coated board is the color of the simulation is very high; roller coating process of good and bad grade difference is very big, in addition to all the materials related to, there is also with it a few times on the color, such as two coated two rolls, that is, spraying a baked once, and then re-sprayed and then baked, so that the color will be more uniform and smooth, a good roller coated board prices are also very expensive, the color is realistic, long-lasting.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust