Language

▼

Language

▼

More Language

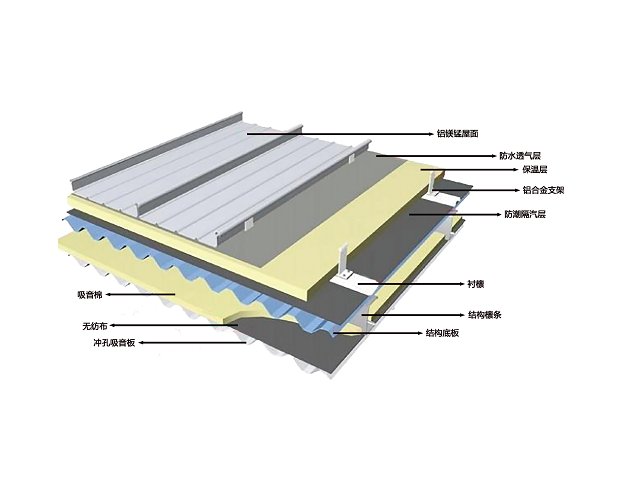

Aluminum magnesium manganese plate is a very cost-effective roofing, exterior wall material. Aluminum alloy has been widely used in the construction industry, and has played an important role in the development of modern buildings to the direction of comfort, light weight, durability, economy and environmental protection. AA3004 aluminum magnesium manganese alloy due to moderate structural strength, weather resistance, water resistance, easy bending welding processing and other advantages, is generally recognized as a building design life of more than 20 years of roof, exterior wall materials.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust