Language

▼

Language

▼

More Language

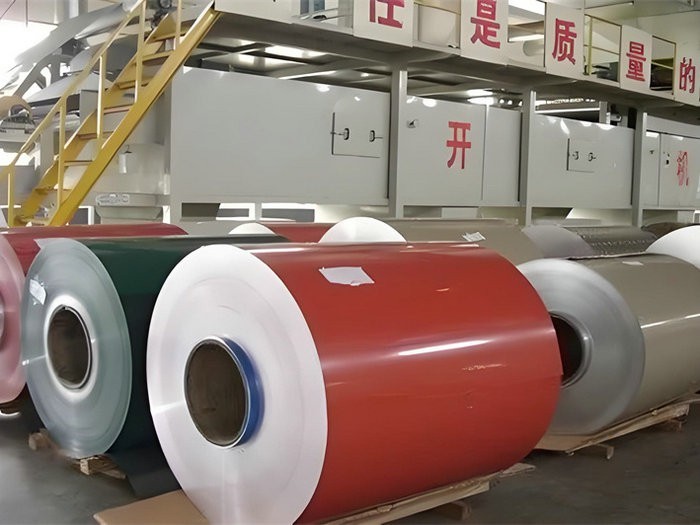

The color coated weight plate has good processing performance, mainly due to its unique material and structural design. The following is a detailed analysis of the processing performance of color coated weight plates:

High quality metal substrates are usually used, such as cold-rolled steel plates or aluminum magnesium zinc coated steel plates, which have good machinability. During the processing, various cutting tools such as scissors, saw blades, or laser cutting machines can be used to easily cut the color coated weight plate into the desired shape and size.

The coating of the color coated weight plate has good adhesion with the substrate, which makes it less prone to coating peeling or cracking during bending and stamping processes. Meanwhile, the strength and rigidity of the substrate can also meet the processing requirements of various complex shapes and structures. Therefore, it performs well in manufacturing various curved and stamped parts.

The substrate of the color coated weight plate has good weldability and can be firmly connected to other metal materials through various welding methods such as resistance welding, gas shielded welding, etc. During the welding process, the coating is usually not greatly affected, so the welded parts can still maintain good decorative and corrosion resistance.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust