Language

▼

Language

▼

More Language

To determine whether the quality of galvanized sheet metal sheets is good, comprehensive considerations can be made from the following aspects:

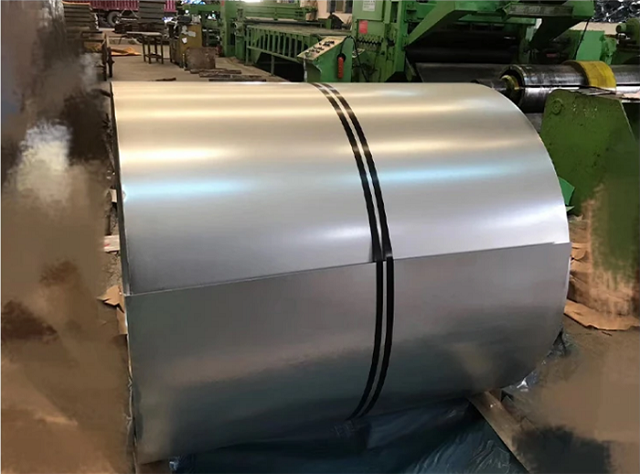

Excellent galvanized sheet metal sheets has a smooth and flat surface, without cracks, rust spots, and obvious color differences. When touched by hand, it should feel even and delicate, without any unevenness. The color should be bright and uniform. If the color is uneven or there is obvious color difference, it may be due to uneven coating or signs of rust. The edges should be intact without gaps or sharp edges to reduce the risk of damage during processing.

Use professional measuring tools (such as vernier calipers) to check the thickness of galvanized sheet metal sheets, ensuring that the thickness is uniform, there are no significant differences in thickness, and meets the requirements specified in the contract or standard. Check whether the length, width, and other specifications of the galvanized sheet metal sheets are consistent, and whether the nominal size on the goods label matches the actual size.

A good galvanized sheet metal sheets coating should be uniform, strong, able to adhere well to the steel plate, and not easily peel off. Observe whether the coating surface is smooth and flat, and whether there are obvious thickness differences and defects such as bubbles. At the same time, excellent galvanized sheet metal sheets coatings should have good corrosion resistance and be less prone to rusting even in humid environments.

Excellent galvanized sheet metal sheetss are usually packaged in standard packaging, such as iron sheet packaging lined with moisture-proof paper, and firmly tied with iron waists to prevent friction between the galvanized sheet metal sheetss inside. During transportation, it should be ensured that the galvanized sheet metal sheets is not damaged, avoiding scratches, deformations, or moisture.

Verify the tensile strength of galvanized sheet metal sheets through tensile testing to ensure that it can withstand certain tensile and compressive forces during use. Measure the process performance of galvanized sheet metal sheets through bending test. Generally speaking, excellent galvanized sheet metal sheetss should not have zinc layer detachment on the outer surface after bending 180 degrees, and the substrate should not have cracking or fracture phenomena.

China galvanized plate manufacturer: Boxing Shuangshengda Steel specializes in galvanized sheet, galvanized steel plate,Colour steel plate etc.We have a full range of product specifications and types, low prices, and more than 20 years of experience, worthy of your trust